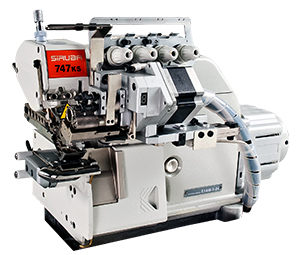

700KS/700KST

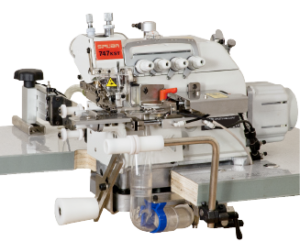

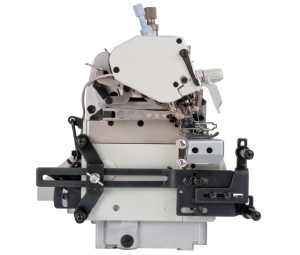

700KS High Speed Cylinder Bed Overlock Machine

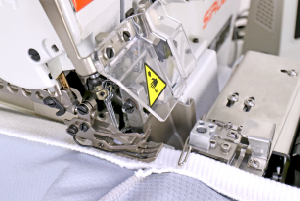

700KST High Speed Cylinder Bed Top Feed Overlock Machine

-

Buy it now

Buy it now

Choose Model

| Specification index | ||

|---|---|---|

| ① Thread numbers | ④ Sewing Fabric/Upper Looper capacity | ⑦ Overedge width |

| ② Model | ⑤ Feed dog type | ⑧ Device |

| ③ Sewing types | ⑥ Needle gauge | ⑨Motor U:U Series H:H Series |

| 700KS |

|

|

|

|

|

|

|

|

| OPTIONAL DEVICE ⑧ | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blindstitch Hemming | 737KS-505F-2-04/⑨ | 1 | 3 | – | 4 | 0.7-2 | 3.8 | 5 | #9 | 6500 | VT, LFD6K-□, RLK-□ | |

| General Sewing | 737KS-504M-3-0⑦/⑧/⑨ | 1 | 3 | – | 3,4,5 | 0.7-2 | 3.8 | 5 | #11 | 6500 | VT, LFD6K-□, RLK-□ | |

| General Sewing | 737KS-504H-3-0⑦/⑧/⑨ | 1 | 3 | – | 3,4,5 | 0.7-2 | 3.8 | 6 | #11 | 6300 | VT, LFD6K-□, RLK-□ | |

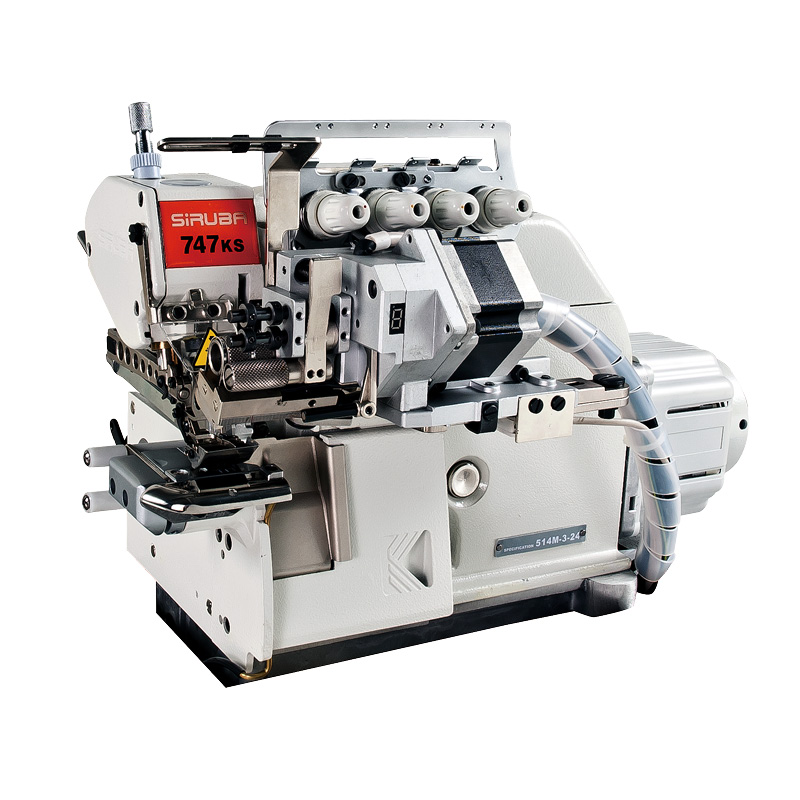

| General Sewing | 747KS-514M-3-2⑦/⑧/⑨ | 2 | 4 | 2 | 3,4,5 | 0.7-2 | 3.8 | 5 | #11 | 6500 | VT, LFD6K-□, RLK-□ | |

| General Sewing | 747KS-514H-3-2⑦/⑧/⑨ | 2 | 4 | 2 | 3,4,5 | 0.7-2 | 3.8 | 6 | #11 | 6300 | VT, LFD6K-□, RLK-□ | |

| 700KST | ||||||||||||

| Blindstitch Hemming | 737KST-505F-2-04/⑨ | 1 | 3 | – | 4 | 0.7-2 | 0.5~6 | 3.8 | 5 | #9 | 6300 | VT, RLK-□ |

| General Sewing | 737KST-504M-3-0⑦/⑧/⑨ | 1 | 3 | – | 3,4,5 | 0.7-2 | 0.5~6 | 3.8 | 5 | #11 | 6300 | VT, RLK-□ |

| General Sewing | 737KST-504H-3-0⑦/⑧/⑨ | 1 | 3 | – | 3,4,5 | 0.7-2 | 0.5~6 | 3.8 | 6 | #11 | 6000 | VT, RLK-□ |

| General Sewing | 747KST-514M-3-2⑦/⑧/⑨ | 2 | 4 | 2 | 3,4,5 | 0.7-2 | 0.5~6 | 3.8 | 5 | #11 | 6300 | VT, RLK-□ |

| General Sewing | 747KST-514H-3-2⑦/⑧/⑨ | 2 | 4 | 2 | 3,4,5 | 0.7-2 | 0.5~6 | 3.8 | 6 | #11 | 6000 | VT, RLK-□ |

700KS High Speed Cylinder Bed Overlock Machine

700KST High Speed Cylinder Bed Top Feed Overlock Machine

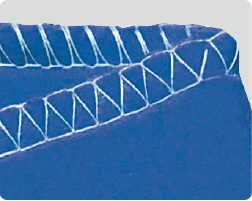

Succeeding 700K Series’ features, we develop cylinder bed mechanism to extend to 700KS Series. Moreover, with brand new independent-drive top feed mechanism, it extends to 700KST Series.

‧ Cylinder Bed Circumference: 148mm

‧ Stitch Length Adjustment: Push-button

‧ Differential Feed Ratio Adjustment: Lever type

‧ Lubrication: Fully-automatic

Exclusive Optional Attachment

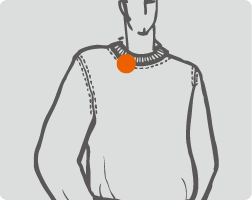

CIRCULAR COLLAR ATTACHING SERIES

RSK Circular collar & Waistband attaching device

1. Pneumatic fabric guider set holds the neckband’s right and left side. With tubular extending roller set, the neckband tape can move forward stably so that operators can focus on fabric control, which improves the efficiency and reduces the difficulty of sewing operation.

2. The alignment device makes fabric edge aligned,shift-free during sewing.

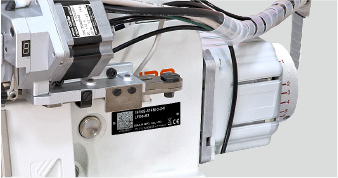

3. Equipped with Hohsing direct-drive energy saving motor.

*For circular collar & waistband sewing.

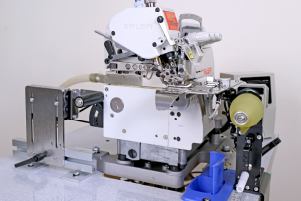

ACS200 Automatic circular collar attaching device

Auto detect the collar seam, by sensor. shorten the rib marking time.

Tubular tension control system avoids puckering.

Guiding platform ensures a quality joint of rib and fabrics.

Automatically control the fabric feeding.

| Model | ACS200 |

|---|---|

| Machine Head | SIRUBA 747KST-514M-3-24/VT |

| Sewing Speed | 4500 SPM (Max ) |

| Type of Fabric | Elastic fabric |

| Needle Type | DC x 27 #11 |

| Stitch Length | 0.5~6 mm |

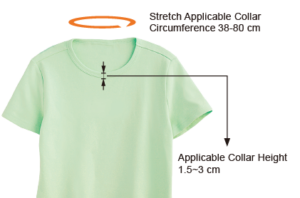

| Applicable Collar Circumference |  |

| Applicable Collar Height |

|

| Applicable Cloth Thickness | After fold 1.2 mm ±0.2 mm |

| Air Consumption | 150 L/min |

| Air Pressure | 0.5 MPa |

| Power Supply | Single Phase 1Φ AC200~240V 50/60Hz |

| Power Consumption | 650 W ( Max ) |

| Dimensions | (W)1200×(D)670×(H)1600mm( With table and thread stand ) |

| Production Capacity | Sewing speed: 4000 SPM、Cycle time: 180-240 pcs / Hr |

LFD6K Multi-function computerized automatic elastic attaching

For attaching elastic tape on small openings of swimsuit, leotards or brief, etc. By computer control, with auto cutting and auto tape feeding, elastic tape sewing can be done by multi-section tension and length.

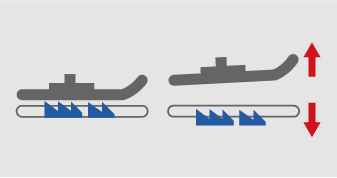

Feed dog dropping function : when presser foot lifts, the feed dog drops to ensure tape feeding without obstacle.

Direct drive servo motor : Electrics highly integration realizes the accurate series movements.

TAPE FEEDING / CUTTING

● 3 operation modes: Auto, Manual, and Test. Auto/ Manual section changing with LED indicate lamp.

● Precise feeding and the length setting unit is mm.

● Adjustable feeding of forward, delay, reverse, and forward feeding with reverse function.

● Speed compensation with 10 default values for choice.

● For different sewing situations, active feeding may be applied by forward/ reverse ‧when sewing.If sewing operation failed, auto/ manual return to the first section of sewing program.

● Air blow tape feeding function.

SETTING /MEMORY

● Memory of sewing program set: 10 sets

● Program section: 18 sections.

● LCD panel shows setting status, operation mode, and error code.

Additional Function

● Thread releasing

● Suction trimmer’s energy saving: Starting/ Ending air suction’s time is adjustable. (by stitch counting)

● Auto presser foot lifting by paddle step-back.

LFD6 SPECIFICATION

| Program set memory | 10 sets |

| Sections of every program | 18 sections |

| Tape feeding length per stitch | 0.2mm~6.5mm |

| Max. Speed (stitch length 5mm) | 4200 R.P.M |

| Encoder (synchronizer) | 48-pulse |

| Tape feeding motor | 5-phase stepping motor |

| Voltage | AC 110~220 V |

▼Applicable to non-direct-drive type

| Code | Description | Remark |

| LFD6-A | Short roller: for tape width 16 mm below | Standard |

| LFD6-AA | Long roller: for tape width range 16mm~50mm | Standard |

| LFA | Electric tape feeding device (Voltage 110~ 220V) | Optional |

| LF290 | Euntangling wheel □=Voltage LFR-1: 110V, LFR-2: 220V) | Optional |

| VT * | Vertical Pneumatic chain cutter | Standard |

| TU* | Dust collector suction device | Standard |

RLK1 Tubular Extending Roller set Diagonal extending roller with closed table top

RLK2

Tubular Extending Roller set

Diagonal extending roller

with open table top

RLK3

Tubular Extending Roller set

Three point extending roller

with open table top

RLK3P

Tubular ExtendingRoller set

(pneumatic)

‧Three point extending roller

with open table top

‧ Recommend Package

TUA-38S(ST) / DKH201ADE-A/

700KS-T3-P