700L

700L series

- See introduction to motors

SPECIFICATION

| Specification index | ||

|---|---|---|

| ① Thread numbers | ④ Sewing Fabric/Upper Looper capacity | ⑦ Overedge width |

| ② Model | ⑤ Feed dog type | ⑧ Device |

| ③ Sewing types | ⑥ Needle gauge | ⑨Motor U:U Series H:H Series |

| 700L |

|

|

|

|

|

|

|

|

| ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| General Seaming | 737L-503M-3-04 |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 7500 |

| General Seaming | 737L-504F-2-04 |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 5 | #11 | 7500 |

| General Seaming | 737L-504M-3-0⑦ |

| 1 | 3 | – | 4,5 | 0.7-2 | 3.6 | 6 | #11 | 7500 |

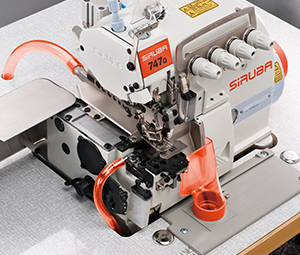

| General Seaming | 747L-512M-3-25 |

| 2 | 4 | 2 | 5 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| General Seaming | 747L-512M-3-34 |

| 2 | 4 | 3 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| General Seaming | 747L-514M-3-2⑦ |

| 2 | 4 | 2 | 3,4,5 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| General Seaming | 747L-514H-3-28 |

| 2 | 4 | 2 | 8 | 0.7-2 | 3.6 | 4 | #11 | 6500 |

| General Seaming | 757L-516L-2-24 |

| 2 | 5 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #14 | 7500 |

| General Seaming | 757L-516L-2-35 |

| 2 | 5 | 3 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7500 |

| General Seaming | 757L-516M-3-35 |

| 2 | 5 | 3 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7500 |

| General Seaming | 757L-516M-3-55 |

| 2 | 5 | 5 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7500 |

| General Seaming | 767L-644M-3-324 |

| 3 | 6 | 3+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| General Seaming | 767L-644M-3-524 |

| 3 | 6 | 5+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Fine Edging | 737L-504F-2-02/GAL |

| 1 | 3 | – | 2 | 0.7-2 | 3.6 | 5 | #9 | 7500 |

| Fine Edging | 737L-504F-2-15 |

| 1 | 3 | – | 1.5 | 0.7-2 | 3.6 | 5 | #9 | 7500 |

| Fine Edging | 737L-504M-2-15 |

| 1 | 3 | – | 1.5 | 0.7-2 | 3.6 | 6 | #9 | 7500 |

| Tape Inserting | 747L-514M-3-2⑦/TG |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| Blind Hemming | 737L-505F-2-04 |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 5 | #9 | 7500 |

| Elastic Attaching | 737L-504M-3-04/LFC-3 |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 4500 |

| Elastic Attaching | 737L/WR/LFC-3 |

| 1 | 3 | – | – | – | – | – | #11 | 4500 |

| Elastic Attaching | 747L-514M-3-2⑦/LFC-3 |

| 2 | 4 | 2 | 4,5 | 0.7-2 | 3.6 | 5.5 | #11 | 4500 |

| Gathering | 747L-514M-8-24/GA |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Gathering | 757L-516M-8-35/GA |

| 2 | 5 | 3 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Gathering | 757L-516M-8-55/GA |

| 2 | 5 | 5 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Manual Back Latching Seaming | 737L-504M-7-04/BK |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 7500 |

| Manual Back Latching Seaming | 747L-514M-7-2⑦/BK |

| 2 | 4 | 2 | 3,4 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| Manual Back Latching Seaming | 747L-514H-7-2⑦/BK |

| 2 | 4 | 2 | 4,5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Fully Auto Back Latching Seaming | 737L-504M-3-0 ⑦ /BKF |

| 1 | 3 | – | 3,4,5 | 0.7-2 | 3.6 | 6 | #11 | 7500 |

| Fully Auto Back Latching Seaming | 747L-514M-3-2 ⑦ /BKF |

| 2 | 4 | 2 | 3,4 | 0.7-2 | 3.6 | 5.5 | #11 | 7500 |

| Over Seaming On Bulky Knitwear | 747L-514H-4-24 |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Over Seaming On Bulky Knitwear | 747L-514H-4-25 |

| 2 | 4 | 2 | 5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Jeans Safety Stitch | 757L-516H-3-5 ⑦ |

| 2 | 5 | 5 | 5,6 | 0.7-2 | 3.6 | 7 | #16 | 6000 |

| Jeans Safety Stitch | 757L-516X-3-5 ⑦ ※ |

| 2 | 5 | 5 | 5,6 | 0.7-2 | 3.6 | 7 | #16 | 6000 |

| Tape Inserting On Bulky Knitwear | 747L-514H-4-24/TG |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Tape Inserting On Bulky Knitwear | 747L-514H-4-25/TG |

| 2 | 4 | 2 | 5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Pocket Binding | 757L-516M-3-35/PS |

| 2 | 5 | 3 | 5 | 0.7-2 | 3.6 | 5 | #14 | 7000 |

| Pocket Binding | 757L-516M-3-55/PS |

| 2 | 5 | 5 | 5 | 0.7-2 | 3.6 | 5 | #14 | 7000 |

| Pocket Binding | 757L-401M-8- ⑥ 0/TA | 2 | 4 | 3,5 | – | 0.7-2 | 3.6 | 5 | #14 | 7000 | |

| Pneumatic type tape/Thread cutter | 737L-504M-3-04/ECA(-U) |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 7000 |

| Pneumatic type tape/Thread cutter | 747L-514M-3-24/ECA(-U) |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Pneumatic type tape/Thread cutter | 747L-514M-3-24/ECA/BKT |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Pneumatic type tape/Thread cutter | 747L-514H-3-28/ECA(-U) |

| 2 | 4 | 2 | 8 | 0.7-2 | 3.6 | 4 | #11 | 6500 |

| Pneumatic type tape/Thread cutter | 747L-514H-4-25/ECA-U |

| 2 | 4 | 2 | 5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Pneumatic type tape/Thread cutter | 757L-516M-3- ⑥ 5/ECA(-U) |

| 2 | 5 | 3.5 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Pneumatic type tape/Thread cutter | 757L-516H-3-55/ECA-U |

| 2 | 5 | 5 | 5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Pneumatic type tape/Thread cutter | 757L-516X-3-56/ECA-U |

| 2 | 5 | 5 | 6 | 0.7-2 | 3.6 | 7 | #16 | 6000 |

| Pneumatic type tape/Thread cutter | 767L-644M-3-324/ECA-U |

| 3 | 6 | 3+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Solenoid type tape/Thread cutter | 737L-504M-3-04/ECB(-U) |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 7000 |

| Solenoid type tape/Thread cutter | 747L-514M-3-2 ⑦ /ECB(-U) |

| 2 | 4 | 2 | 3,4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Solenoid type tape/Thread cutter | 747L-514H-3-28/ECB |

| 2 | 4 | 2 | 8 | 0.7-2 | 3.6 | 4 | #11 | 6500 |

| Solenoid type tape/Thread cutter | 747L-514M-3-23/ECB-U |

| 2 | 4 | 2 | 3 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Solenoid type tape/Thread cutter | 747L-514H-4-25/ECB-U |

| 2 | 4 | 2 | 5 | 0.7-2 | 3.6 | 7 | #16 | 6500 |

| Solenoid type tape/Thread cutter | 757L-516M-3- ⑥ 5/ECB(-U) |

| 2 | 5 | 3,5 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Solenoid type tape/Thread cutter | 757L-516X-3-56/ECB-U |

| 2 | 5 | 5 | 6 | 0.7-2 | 3.6 | 7 | #16 | 6000 |

| Solenoid type tape/Thread cutter | 767L-644M-3-324/ECB(-U) |

| 3 | 6 | 3+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Solenoid type tape/Thread cutter | 767L-644M-3-524/ECB-U |

| 3 | 6 | 5+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Side Suction Chain-Cutter (With Sensor-Controlled Energy) | 737L-504M-3-04/VTE(-U) |

| 1 | 3 | – | 4 | 0.7-2 | 3.6 | 6 | #11 | 7000 |

| Side Suction Chain-Cutter (With Sensor-Controlled Energy) | 737L-504F-2-15/ VTE |

| 1 | 3 | – | 1.5 | 0.7-2 | 3.6 | 6 | #9 | 7000 |

| Side Suction Chain-Cutter (With Sensor-Controlled Energy) | 747L-514M-3-24/ VTE(-U) |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Side Suction Chain-Cutter (With Sensor-Controlled Energy) | 747L-514H-3-28/ VTE |

| 2 | 4 | 2 | 8 | 0.7-2 | 3.6 | 4 | #11 | 6500 |

| Side Suction Chain-Cutter (With Sensor-Controlled Energy) | 747L-514M-3-24/ VTA |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Flat Suction Chain-Cutter ( With Sensor-Controlled Energy-Saving Device ) | 747L-514M-3-24/ CTE |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

| Flat Suction Chain-Cutter ( With Sensor-Controlled Energy-Saving Device ) | 757L-516L-2-24/ CTE |

| 2 | 5 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Flat Suction Chain-Cutter ( With Sensor-Controlled Energy-Saving Device ) | 757L-516M-3-35/ CTE |

| 2 | 5 | 3 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Flat Suction Chain-Cutter ( With Sensor-Controlled Energy-Saving Device ) | 757L-516M-3-55/ CTE |

| 2 | 5 | 5 | 5 | 0.7-2 | 3.6 | 5.5 | #14 | 7000 |

| Flat Suction Chain-Cutter ( With Sensor-Controlled Energy-Saving Device ) | 757L-516X-3-56/ CTE ※ |

| 2 | 5 | 5 | 6 | 0.7-2 | 3.6 | 7 | #16 | 6000 |

| Horizontal Pneumatic Type Chain Cutter (Flat Suction) | 767L-644M-3-324/CT |

| 3 | 6 | 3+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Horizontal Pneumatic Type Chain Cutter (Flat Suction) | 767L-644M-3-524/CT |

| 3 | 6 | 5+2 | 4 | 0.7-2 | 3.6 | 5 | #11 | 7000 |

| Electric Type Tape/Elastic Cutter | 747L-514M-3-24/ EC |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 6500 |

| Top and bottom anticurly material | 747L-514M-3-24/VT/UC |

| 2 | 4 | 2 | 4 | 0.7-2 | 3.6 | 5.5 | #11 | 7000 |

700L series

Based on SiRUBA overlock technology, we greatly enhance the performance.

700L DD Motor Series

Based on the rich experience of 700QD Series, SiRUBA upgrades the control technology.

700L

| Direct-drive Control Set | Device | Function | Accessory List | ||||||||||||

| Sensor | Safety Switch | Control Panel | Manual Cut Switch | Thread Release | Tape Cutter | Suction Trimmer | LED Light | Standing Operation Padel | Auto Foot Lifter | Suction Set | Needle Plate |

||||

| Side Cutter | Flat Cutter |

||||||||||||||

| DKLH□-0 Economic Type | / | General Sewing | ● | Standard | |||||||||||

| VT | Suction Thread Trimmer | ● | ● | #4 | #3 #4 |

||||||||||

| CT | Suction Thread Trimmer | ● | ● | #4 | #3 #4 |

||||||||||

| EC | Electric Type Tape Cutter | ● | ● | ● | |||||||||||

| DKLH□-1 Multi-function Pneumatic Type | ECA | Air Type Tape Cutter | ● | ● | ● | ● | ● | ● | #2 | ● | ● | ||||

| VTE | Suction Thread Trimmer | ● | ● | ● | #1 | ● | ● | #2 | ● | ● | |||||

| VTA | Suction Thread Trimmer | ● | ● | ● | #1 | ● | ● | #2 | ● | ● | |||||

| CTE | Suction Thread Trimmer | ● | ● | ● | #1 | ● | ● | #2 | ● | ● | |||||

| UC | Top and Bottom Anti-Curly Edge | ● | ● | ● | ● | #2 | ● | ● | |||||||

| BKT | Simplied Auto Back Latch | ● | ● | ● | ● | ● | ● | #2 | ● | ● | |||||

| DKLH□-2 Multi-function Electric Type | ECB | Electric Type Tape Cutter | ● | ● | ● | ● | ● Solenoid Type | ● | #2 | ● Solenoid Type | #3 | ||||

| DKLU□-0 Economic Type | / | General Sewing | ● | Standard | |||||||||||

| DKLU□-1 Multifunction Type | ECA-U | Air Type Tape Cutter | ● | ● | ● | ● | ● | ● | #2 | ● | ● | Long type | |||

| ECB-U | Electric Type Tape Cutter | ● | ● | ● | ● | ● | ● | #2 | ●Solenoid Type | ● | |||||

| VTE-U | Suction Thread Trimmer | ● | ● | ● | ● | ● | ● | ● | #2 | ● | ● | ||||

| CTE | Suction Thread Trimmer | ● | ● | ● | ● | ● | ● | #2 | ● | ● | |||||

Product Package: Devices and Direct-Drive Control Sets

●Standard accessory : The suction set is standard accessory of 700L sensor type models.

# Optional accessory

#1: BK321-4

#2: EC467-A

#3: ①TUA-31 Air compressor is required.

②TUD-2 Driven by Brushless motor.

#4: TUA-32K Air compressor is required.

3-IN-1 SUCTION DEVICE

Remark: ECB optional device